When we first began to lay out the plans for this house, on our tiny lot that was only 21 feet wide and 50 feet deep, I thought we would be building a small house. But with some creative space planning, we managed to maximize the space so much that I am continuously impressed with how big it feels.

Now that the framing is complete and the exterior has been wrapped with plywood sheathing giving the frame more stability, we were able to take the bracing out of the interior and finally see the whole space.

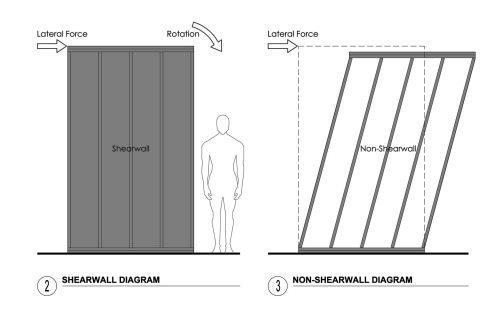

Since the first floor is pretty much one big open space without any walls, we included a couple structural “shear walls” in the design, which act like book ends to help brace the exterior walls from moving side to side.

One shear wall is located between the living room and the kitchen to hide the side of the cabinets for a more “built-in” look. The second shear wall is at the end of the living room to hide the side of the TV cabinets and built-in bookshelves.

The stair to the second floor is framed out along with a small half bath and storage closet under the stairs.

The second floor landing at the top of the stairs is open all the way up to the angled roof, making even this small space feel huge and grand.

The walls for the bedrooms on the second floor align with the shear walls below, tying the whole structure together.

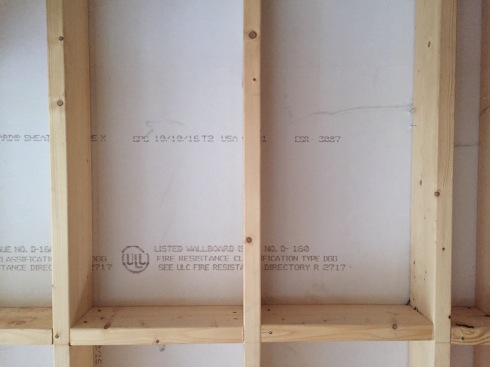

Since we received a variance that allowed us to build all the way to the property line on one side, the exterior wall on that side is required by code to be 1 hour fire rated. To achieve the fire rating, we used a non-combustible gypsum sheathing (the name brand is DensGlass) in lieu of plywood sheathing on this wall.

Even though in our case there is no adjacent structure on this side, the intent of the code is to prevent the spread of a fire from one building to the next when the buildings are in close proximity. The interior of the wall will be finished with drywall to look identical to the other walls in the house.

Now that the roof joists have been installed, they are being secured with metal straps to keep the roof from blowing off in the event of a hurricane (these straps are often referred to as “hurricane ties”).

The composition of the roof itself is designed to maximize energy efficiency by creating a high thermal barrier. The composition of the roof from exterior to interior is:

- Standing seam metal roof

- Self-adhered ice and water shield membrane/roof underlayment

- (2) layers continuous 1/2″ rigid polyiso insulation, with staggered joints and foil faced top layer.

- Plywood sheathing

- Open cell spray foam insulation

- Wood roof rafters

- Gypsum Board

Since the house does not have a typical attic space to trap heat, and the top floor is occupied, it was important to prevent as much heat from entering the space as possible in the summer, and to keep as much heat as possible inside the space in the winter. The metal roof and water shield membrane are there to keep water out. Everything below that is designed to keep heat out/in. The rigid insulation is applied in two layers in order to stagger the joints, so there are no weak points at the seams. Foil is a “low-emissivity” material, so the foil-faced top layer reflects radiant energy (heat from the sun), which greatly improves the thermal resistance of the roof. The plywood sheathing gives a solid surface to attach all these layers to the roof, and the spray foam insulation seals the deal to create a thermally awesome system. Goodbye high energy bills.

Now that framing is complete, the crew is starting to make the building water-tight by wrapping the exterior with a water barrier (Tyvek).

The next step will be to install the windows, which were delivered this week. After much research on window specifications and quotes from various manufacturers, we decided to order the windows from Milgard, who carries contemporary aluminum windows with great thermal energy performance. However, the closest distributor was in Houston so we had to arrange for crating and freight delivery.

Organizing the logistics for the delivery was a frustrating process, to say the least, which involved multiple trucks, a rented forklift, and a broken crate. The windows all arrived in good condition (whew!) and after all was said and done, they look great.

“A world which sees art and engineering as divided is not seeing the world as a whole.” – Sir Edmund Happold

(Alternate Post Title: “Been There Done That, We Got Walls, We Got Straps“)